Toyota CH-R Service Manual: Inspection

INSPECTION

PROCEDURE

1. INSPECT TRANSMISSION REVOLUTION SENSOR (NIN)

|

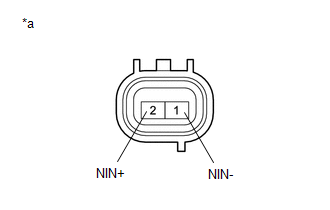

*a |

Component without harness connected (Transmission Revolution Sensor (NIN)) |

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 (NIN-) - 2 (NIN+) |

20°C (68°F) |

560 to 680 Ω |

If the result is not as specified, replace the transmission revolution sensor (NIN).

2. INSPECT TRANSMISSION REVOLUTION SENSOR (NOUT)

(a) Connect the battery to the transmission revolution sensor (NOUT) as shown in the illustration.

|

(b) Wave a magnetic object left and right in front of the tip of the transmission revolution sensor (NOUT) (5 mm (0.197 in.) gap or closer) to change the high/low signals while measuring the current. NOTICE: Be sure to wave a magnetic object during the inspection. The current will not change without waving the magnetic object as indicated by the arrow in the illustration. |

|

(c) Measure the current according to the value(s) in the table below.

Standard Current:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 (NOTO) - 2 (NOTB) |

Low Signal |

4 to 8 mA |

|

High Signal |

12 to 16 mA |

If the result is not as specified, replace the transmission revolution sensor (NOUT).

3. INSPECT TRANSMISSION REVOLUTION SENSOR (NT)

(a) Connect the battery to the transmission revolution sensor (NT) as shown in the illustration.

|

(b) Wave a magnetic object left and right in front of the tip of the transmission revolution sensor (NT) (5 mm (0.197 in.) gap or closer) to change the high/low signals while measuring the current. NOTICE: Be sure to wave a magnetic object during the inspection. The current will not change without waving the magnetic object as indicated by the arrow in the illustration. |

|

(c) Measure the current according to the value(s) in the table below.

Standard Current:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 (NTO) - 2 (NTB) |

Low Signal |

4 to 8 mA |

|

High Signal |

12 to 16 mA |

If the result is not as specified, replace the transmission revolution sensor (NT).

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration)

that must be performed after parts are removed, installed, or replaced during th ...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL TRANSMISSION REVOLUTION SENSOR (NT)

(a) Apply Toyota Genuine CVT fluid FE to a new O-ring.

(b) Install the O-ring to the transmission revolution sensor (NT).

(c) ...

Other materials:

Toyota CH-R Service Manual > Seat Belt Warning System(w/ Occupant Classification System): Data List / Active Test

DATA LIST / ACTIVE TEST

DATA LIST

HINT:

Using the Techstream to read the Data List allows the values or states of switches,

sensors, actuators and other items to be read without removing any parts. This non-intrusive

inspection can be very useful because intermittent conditions or signals may ...

Toyota CH-R Service Manual > Forced Release(for Tmmt Made): Operation Method

OPERATION METHOD

PROCEDURE

1. PRECAUTION

Click here

2. REMOVE BENCH TYPE REAR SEAT CUSHION ASSEMBLY

Click here

3. DISCONNECT REAR DOOR OPENING TRIM WEATHERSTRIP LH

Click here

4. DISCONNECT REAR DOOR OPENING TRIM WEATHERSTRIP RH

HINT:

Use the same procedure as for the LH side.

...

Toyota C-HR (AX20) 2023-2025 Owner's Manual

Toyota CH-R Owners Manual

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Toyota CH-R Service Manual

- Introduction

- Maintenance

- Audio / Video

- Cellular Communication

- Navigation / Multi Info Display

- Park Assist / Monitoring

- Brake (front)

- Brake (rear)

- Brake Control / Dynamic Control Systems

- Brake System (other)

- Parking Brake

- Axle And Differential

- Drive Shaft / Propeller Shaft

- K114 Cvt

- 3zr-fae Battery / Charging

- Networking

- Power Distribution

- Power Assist Systems

- Steering Column

- Steering Gear / Linkage

- Alignment / Handling Diagnosis

- Front Suspension

- Rear Suspension

- Tire / Wheel

- Tire Pressure Monitoring

- Door / Hatch

- Exterior Panels / Trim

- Horn

- Lighting (ext)

- Mirror (ext)

- Window / Glass

- Wiper / Washer

- Door Lock

- Heating / Air Conditioning

- Interior Panels / Trim

- Lighting (int)

- Meter / Gauge / Display

- Mirror (int)

- Power Outlets (int)

- Pre-collision

- Seat

- Seat Belt

- Supplemental Restraint Systems

- Theft Deterrent / Keyless Entry

0.01