Toyota CH-R Service Manual: Blower Motor Circuit

DESCRIPTION

The blower motor with fan sub-assembly is operated by signals from the air conditioning amplifier assembly through the blower resistor. Blower motor speed signals are transmitted in accordance with changes in the duty ratio. The blower motor speed becomes slower when the duty interval is wider, and the blower motor speed becomes faster when the duty interval is narrower.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following procedure.

PROCEDURE

|

1. |

PERFORM ACTIVE TEST USING TECHSTREAM (BLOWER MOTOR) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Air Conditioner / Active Test.

(e) Perform the Active Test according to the display on the Techstream.

Body Electrical > Air Conditioner > Active Test|

Tester Display |

Measurement Item |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Blower Motor |

Blower motor with fan sub-assembly |

Min.: 0 Max.: 100 |

Operates between 0 to 100 % |

|

Tester Display |

|---|

|

Blower Motor |

|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

NG (Blower motor with fan sub-assembly does not operate) |

B |

|

NG (Blower motor with fan sub-assembly operates but does not change speed) |

C |

| A | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| C | .gif) |

GO TO STEP 6 |

|

|

2. |

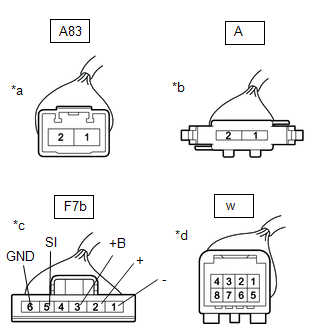

CHECK HARNESS AND CONNECTOR (AIR CONDITIONING HARNESS ASSEMBLY (BLOWER ASSEMBLY) - POWER SOURCE) |

|

(a) Disconnect the air conditioning harness assembly (blower assembly) connector. |

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A83-1 - A83-2 |

Always |

11 to 14 V |

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A83-1 - Body ground |

Always |

Below 1 Ω |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

3. |

INSPECT AIR CONDITIONING HARNESS ASSEMBLY (BLOWER ASSEMBLY) |

(a) Remove the air conditioning harness assembly (blower assembly).

Click here

.gif)

|

(b) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| NG | .gif) |

REPLACE AIR CONDITIONING HARNESS ASSEMBLY (BLOWER ASSEMBLY) |

|

|

4. |

INSPECT AIR CONDITIONING HARNESS ASSEMBLY (HEATER RADIATOR UNIT SUB-ASSEMBLY) |

(a) Remove the air conditioning harness assembly (heater radiator unit sub-assembly).

Click here

.gif)

|

(b) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| NG | .gif) |

REPLACE AIR CONDITIONING HARNESS ASSEMBLY (HEATER RADIATOR UNIT SUB-ASSEMBLY) |

|

|

5. |

INSPECT BLOWER RESISTOR |

(a) Reconnect the F7b blower resistor connector.

(b) Reconnect the w air conditioning harness assembly (blower assembly) connector.

|

(c) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

| NG | .gif) |

REPLACE BLOWER RESISTOR |

|

|

6. |

INSPECT AIR CONDITIONING AMPLIFIER ASSEMBLY |

(a) Reconnect the F72 and F7A air conditioning amplifier assembly connectors.

(b) Turn the ignition switch ON.

(c) Turn the blower switch Lo.

(d) Connect an oscilloscope to terminals F72-29 (GND) and F7A-40 (BLW) of the air conditioning amplifier assembly and check the waveform.

OK:

Waveform is similar to that shown in the illustration.

HINT:

The waveform varies with the blower speed.

|

Item |

Content |

|---|---|

|

Tool Setting |

2 V/DIV., 1 ms./DIV. |

|

Vehicle Condition |

|

|

*a |

Component with harness connected (Air Conditioning Amplifier Assembly) |

- |

- |

| NG | .gif) |

REPLACE AIR CONDITIONING AMPLIFIER ASSEMBLY |

|

|

7. |

REPLACE BLOWER RESISTOR |

(a) Replace the blower resistor with a new or known good one.

Click here

.gif)

|

|

8. |

PERFORM ACTIVE TEST USING TECHSTREAM (BLOWER MOTOR) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Air Conditioner / Active Test.

(e) Perform the Active Test according to the display on the Techstream.

Body Electrical > Air Conditioner > Active Test|

Tester Display |

Measurement Item |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Blower Motor |

Blower motor with fan sub-assembly |

Min.: 0 Max.: 100 |

Operates between 0 to 100 % |

|

Tester Display |

|---|

|

Blower Motor |

| OK | .gif) |

END (BLOWER RESISTOR WAS DEFECTIVE) |

| NG | .gif) |

REPLACE BLOWER ASSEMBLY (BLOWER MOTOR WITH FAN SUB-ASSEMBLY) |

Ambient Temperature Sensor Circuit (B1412)

Ambient Temperature Sensor Circuit (B1412)

DESCRIPTION

The thermistor assembly is installed in front of the cooler condenser assembly

to detect the ambient temperature, which is used to control the air conditioning

system. This sensor is ...

PTC Heater Circuit

PTC Heater Circuit

DESCRIPTION

The air conditioning amplifier assembly sends operation signals to the PTC heater

relays when quick heater assembly operation conditions are met. Based on the signals

from the air con ...

Other materials:

Toyota CH-R Service Manual > K114 Continuously Variable Transaxle Fluid: Components

COMPONENTS

ILLUSTRATION

*1

REFILL PLUG

*2

OVERFLOW PLUG

*3

NO. 1 TRANSMISSION OIL FILLER TUBE

*4

DRAIN PLUG

*5

NO. 1 ENGINE UNDER COVER

*6

REAR ENGINE U ...

Toyota CH-R Service Manual > Back Door Lock: Components

COMPONENTS

ILLUSTRATION

*A

w/ Package Tray Trim

*B

w/ Tonneau Cover

*1

BACK DOOR LOCK ASSEMBLY

*2

BACK DOOR LOCK COVER

*3

BACK DOOR SIDE GARNISH LH

*4

B ...

Toyota CH-R Owners Manual

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Toyota CH-R Service Manual

- Introduction

- Maintenance

- Audio / Video

- Cellular Communication

- Navigation / Multi Info Display

- Park Assist / Monitoring

- Brake (front)

- Brake (rear)

- Brake Control / Dynamic Control Systems

- Brake System (other)

- Parking Brake

- Axle And Differential

- Drive Shaft / Propeller Shaft

- K114 Cvt

- 3zr-fae Battery / Charging

- Networking

- Power Distribution

- Power Assist Systems

- Steering Column

- Steering Gear / Linkage

- Alignment / Handling Diagnosis

- Front Suspension

- Rear Suspension

- Tire / Wheel

- Tire Pressure Monitoring

- Door / Hatch

- Exterior Panels / Trim

- Horn

- Lighting (ext)

- Mirror (ext)

- Window / Glass

- Wiper / Washer

- Door Lock

- Heating / Air Conditioning

- Interior Panels / Trim

- Lighting (int)

- Meter / Gauge / Display

- Mirror (int)

- Power Outlets (int)

- Pre-collision

- Seat

- Seat Belt

- Supplemental Restraint Systems

- Theft Deterrent / Keyless Entry

0.0143

.gif)