Toyota CH-R Service Manual: Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during the headlight assembly removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced|

Replacement Part or Procedure |

Necessary Procedures |

Effects/Inoperative when not performed |

Link |

|---|---|---|---|

|

Headlight ECU sub-assembly LH |

|

Automatic headlight beam level control system |

|

NOTICE:

If the headlight assembly RH is replaced with a new one, vehicle information registration and initialization are not necessary.

HINT:

- Use the same procedure for the RH side and LH side.

- The following procedure is for the LH side.

PROCEDURE

1. REMOVE FRONT BUMPER ASSEMBLY

Click here

.gif)

2. REMOVE HEADLIGHT ASSEMBLY

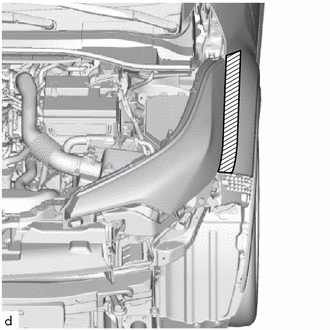

(a) Apply protective tape around the headlight assembly as shown in the illustration.

.png) |

Protective Tape |

(b) Disengage the claw, pull down the connector lock lever as shown in the illustration to disconnect the connector.

|

*a |

Connector Lock Lever |

.png) |

Remove in this Direction |

|

(c) Remove the bolt and 3 screws. |

|

(d) Remove the headlight assembly as shown in the illustration.

.png) |

Remove in this Direction |

Components

Components

COMPONENTS

ILLUSTRATION

*1

HEADLIGHT ASSEMBLY

-

-

N*m (kgf*cm, ft.*lbf): Specified torque

-

-

...

Disassembly

Disassembly

DISASSEMBLY

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH side and LH side.

The following procedure is for the LH side.

PROCEDURE

1. REMOVE HEADLIGHT PROTECTOR ...

Other materials:

Toyota CH-R Service Manual > Maintenance: Rear Side Marker Light Bulb

Components

COMPONENTS

ILLUSTRATION

*1

REAR COMBINATION LIGHT ASSEMBLY

*2

REAR COMBINATION LIGHT COVER

*3

REAR SIDE MARKER LIGHT BULB

*4

REAR COMBINATION LIGHT SOCKET AND WIRE

Removal

REM ...

Toyota CH-R Service Manual > Steering Lock System: Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms.

If multiple suspected areas are listed, the potential causes of the symptoms

are listed in order of probability in the "Suspected Area" column of the

table. Check each sy ...

Toyota CH-R Owners Manual

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Toyota CH-R Service Manual

- Introduction

- Maintenance

- Audio / Video

- Cellular Communication

- Navigation / Multi Info Display

- Park Assist / Monitoring

- Brake (front)

- Brake (rear)

- Brake Control / Dynamic Control Systems

- Brake System (other)

- Parking Brake

- Axle And Differential

- Drive Shaft / Propeller Shaft

- K114 Cvt

- 3zr-fae Battery / Charging

- Networking

- Power Distribution

- Power Assist Systems

- Steering Column

- Steering Gear / Linkage

- Alignment / Handling Diagnosis

- Front Suspension

- Rear Suspension

- Tire / Wheel

- Tire Pressure Monitoring

- Door / Hatch

- Exterior Panels / Trim

- Horn

- Lighting (ext)

- Mirror (ext)

- Window / Glass

- Wiper / Washer

- Door Lock

- Heating / Air Conditioning

- Interior Panels / Trim

- Lighting (int)

- Meter / Gauge / Display

- Mirror (int)

- Power Outlets (int)

- Pre-collision

- Seat

- Seat Belt

- Supplemental Restraint Systems

- Theft Deterrent / Keyless Entry

0.0105